SYSTEM

Product Lineup

- TOP

- Laser-Electronics-ptics(LEO)

- SYSTEM

- Edge/Notch Profile Measurement System

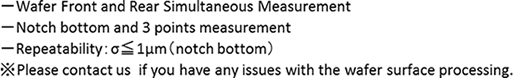

Edge/Notch Profile Measurement System

Edge Profile Monitor Outline

Principle

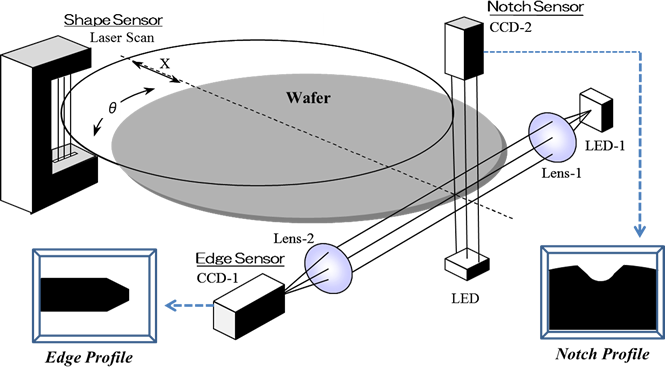

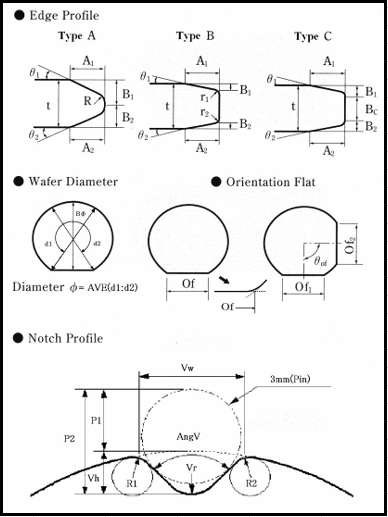

To measure Edge Shape, Notch Shape, Orientation Flat Length, and Wafer Diameter, the system is equipped with 3 independent optical sensor(edge sensor, notch sensor, external shape sensor) .Wafer is vacuum suctioned to a X-θ stage 、and will be able to move the measurement position to edge/notch sensor by translation(X)/rotation(θ)drive.Optical output signal will be transported to image memory. Image processing is performed by software which is installed in the computer.When the image processing is performed, wafer edge, and orientation flat/notch shape is analyzed automatically and each parts length, angle and radius of curvature will be calculated.

Measurement Method and Measurement Items

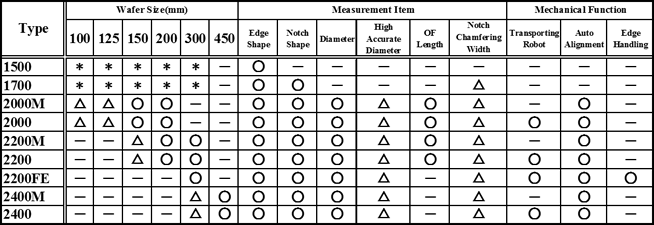

System Lineup

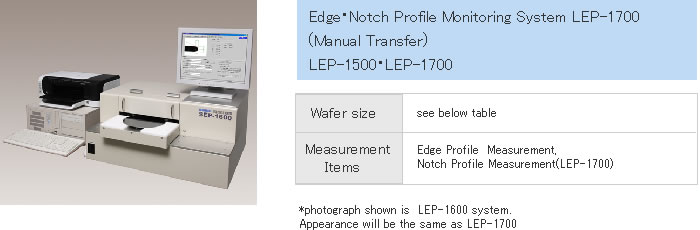

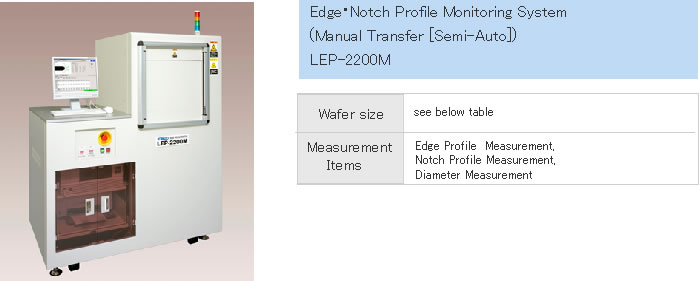

LEP Series

LVM-1400 which it specializes in notch measurement is also available Wafer Size from 6,8,12"φ(Select 2 size)

LVM-1400 which it specializes in notch measurement is also available Wafer Size from 6,8,12"φ(Select 2 size)

Option

Corresponding Size addition.

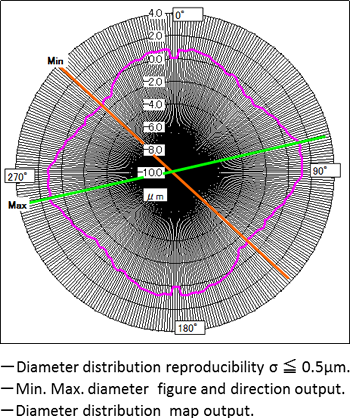

Precision Diameter Measurement

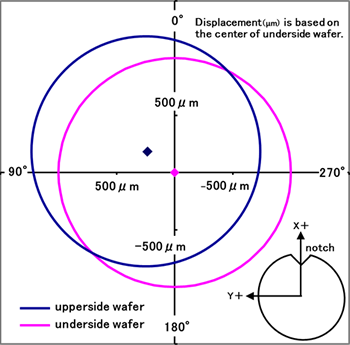

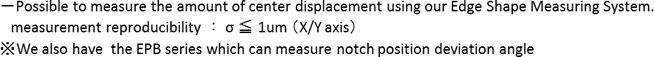

Center Displacement Measurement for Bonding Wafer

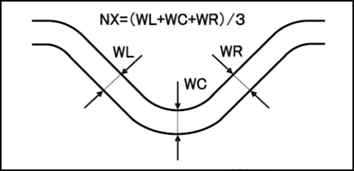

Notch surface width measurement function.(only built in to LEP-2000/2200,2000M/2200M,2200FE)

Simplified notch surface width measurement function.(builtin、possible to modify the existing system ※1。only upper measurement by notch camera)

※1 please contact if the system is supportable

Image data browsing software(Software for checking image data on outside PC)

Orientation flat shoulder R measurement function(2000/2200,2000M/2200M,2200FE builtin、possible to modify the existing system)