SYSTEM

Product Lineup

- TOP

- Laser-Electronics-ptics(LEO)

- SYSTEM

- Edge Roll Off Measuring System

Edge Roll Off Measuring System

Edge Roll Off Measuring System Outline

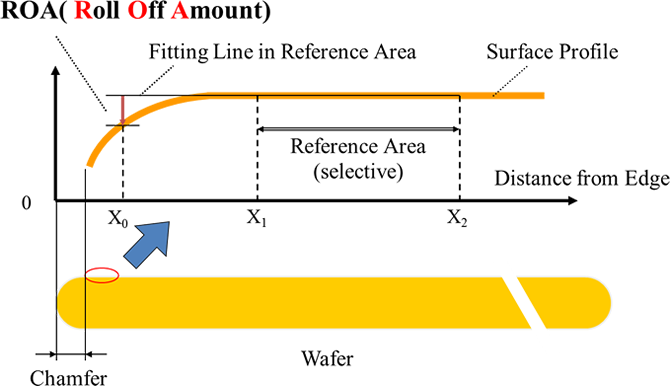

To reduce failure in CMP or lithography process, it is important to manage the profile of the silicon wafers edge. In recent years, edge roll off which represents the deviation from the plane in vicinity of the edge are gaining high profiles As an index to represent the edge roll-off, the parameter ROA(Roll Off Amount) has been proposed. 1)As shown below, ROA represents the difference between fitting line of the reference region that is set as X1~X2 from the edge of the wafer and the actual profile. Larger the ROA the sag is occurring closer to the edger of the wafer 1)M. Kimura, et. al: Jpn. J. Appl. Phys. 38 (1999) pp38.

Principle

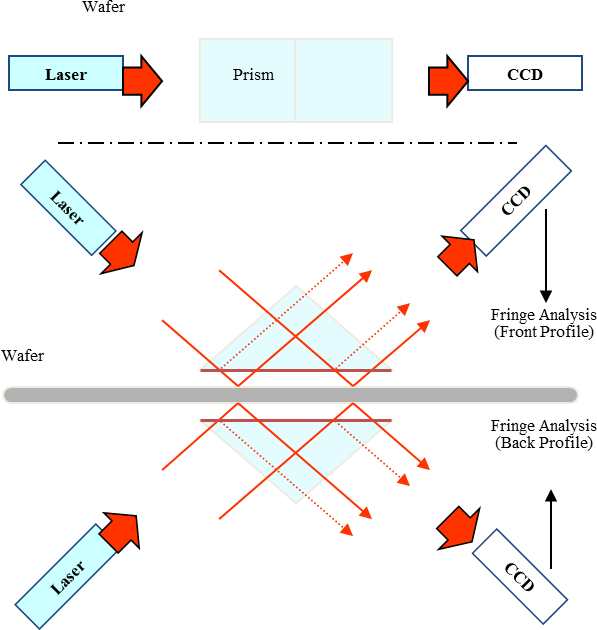

Grading Incidence Interferometer Method (LER series)

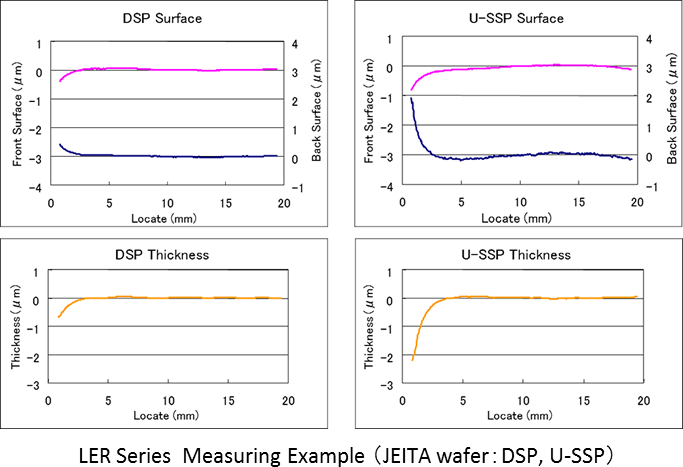

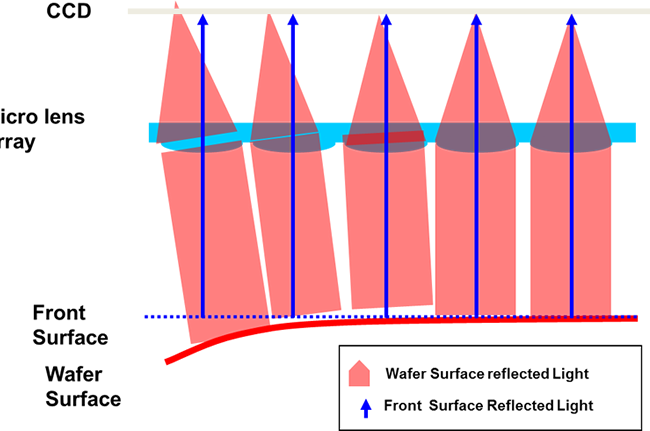

Our Edge Roll Off Measuring System uses Grading Incidence Interferometer Method. Simultaneously the laser beam through prism is irradiated to front and rear surface of the wafer, while changing the distance of the wafer and the prism, it is possible to observe interference fringes using CCD camera.By analyzing the interference fringes to calculate the profile of the front and rear surface of the wafer. And by the profile of the wafer the ROA and thickness will be measured .

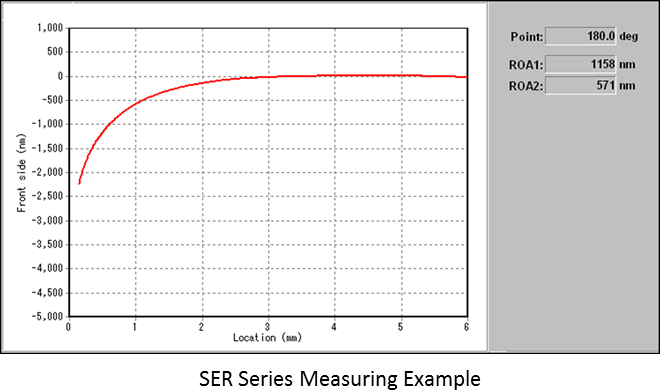

Shack-Hartmann Method (SER Series)

Measuring Example

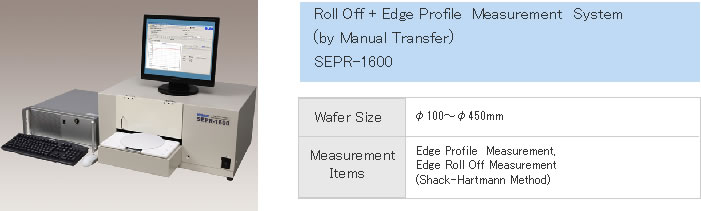

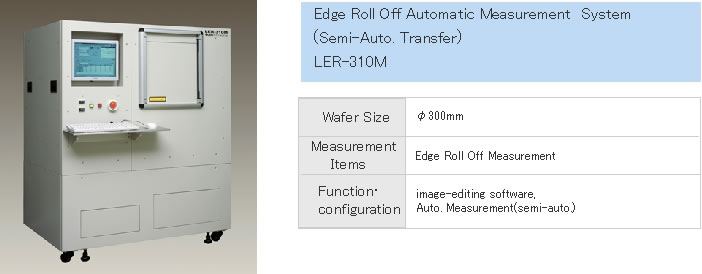

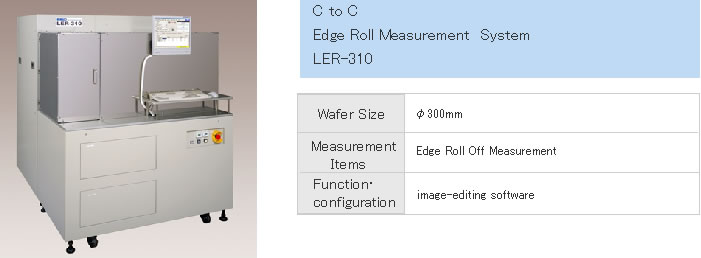

System Lineup

System Features

High-Throughput

Front and Rear Simultaneous Measurement

Non-Contact and Non-Destructive

Option

OHT (Full-Auto) Compatible

Host Communications